CNC-APPS.com Manual

Cutting type

GAS – PLASMA – MARK

One of the three types GAS, PLASMA or MARK has to be chosen in order to proceed.

The differences between the cutting types are:

In GAS and PLASMA type, the program is cutting the holes first. In the contrary, when the MARK type is selected, the program doesn’t focus at the holes and uses the Traveling Salesman Algorithm to engrave the drawing.

DXF arc as polyline

Choosing DXF arc as polyline =“Yes”, the program converts all the arcs of the DXF file into little line segments called polylines and the G-Code file will contain G01 commands. If we choose No instead, the G-Code will be contains arcs G02 or G03 commands.

DXF text as vectors

Choosing DXF text as vectors =“Yes”, the program converts all the TEXT entities into polylines consisted by little line segments (G01).

Kerf distance

Kerf distance is the radius of the tool we are using to cut the material. When the cutting type is “MARK” the program ignores the kerf distance.

Lead-in and Lead-out distance

Lead-in and lead-out are the distance the tool takes to enter the part and the distance to leave it respectively.

Coordinates

Selection |

G-Code command |

Absolute |

G90 |

Incremental |

G91 |

Absolute – incremental Arc centers |

G90 G91.1 |

Measurement unit

Selection |

G-Code command |

Programming in inches |

G20 |

Programming in millimeters (mm) |

G21 |

Programming in centimeters (cm) |

G22 |

M codes on

If Yes then, it will create Μ codes (Machine)

Machine operation |

M code command |

GAS ON |

M1002 |

GAS OFF |

M08 |

PLASMA ON |

M15 |

PLASMA OFF |

M16 |

MARK ON |

M09 |

MARK OFF |

M10 |

END PROGRAMM |

M02 |

Cutting type = GAS

DXF arc as polyline = Yes

DXF text as vectors = No

Kerf distance = 2

Lead in distance = 2

Lead out distance = 2

Coordinates = Absolute

Measurement unit = mm

M codes on = Yes

Outline on = Yes

In the Hatch app the program takes the shape and makes consecutive, parallel lines with same distance between them.

Original drawing

Hatch distance = 2

Outline on = yes

Hatch distance = 2

Outline on = no

In the Punch app the shape must contain spots or small circles so the program can make them into a command (punch command).

Punch command: Is the M command to the machine to punch (ex. M1000).

The Gear to G-Code app help us to make a gear.

Example:

Result

In the Image engraving app we take a grayscale image and the program ‘’prints’’ it by carving the surface of the material. Depending on how dark or light the gray is, is going to determine how deep the tool is going to carve.

Original picture:

Data:

X step: 0.2

Y step: 0.2

Material width: (0=image width) 200

Material height: (0=image height) 150

Material thickness: 30

Min F: 5

Max F: 20

Outline on: no

Negative: no

Result 1:

Data:

Outline on: no

Negative: yes

Result 2:

The same with lower quality.

Data:

X step: 0.5

Y step: 0.5

Result 3:

Original image:

The program identifies which parts are holes and which aren’t. Then, in the holes it puts the kerf distance in the inner direction, and in the remaining parts, in the outer direction.

Thickness: 2

(It is the radius of the tool.)

Reverse kerf direction: no

If we want the process to be done in reverse, then we give Reverse kerf direction = Yes.

DXF arc as polyline: yes

Result: (the kerf is shown with a red line)

In the Punch app we take a surface and the program creates a series of consecutives holes after we have given it the coordinates.

Width: 100 (profile’s width)

Height: 50 (profile’s height)

X offset: 5 (the x coordinate position of the down-left hole)

Y offset: 10 (the y coordinate position of the down-left hole)

Rows: 10

Columns: 5

Punch command: M1000

In Txt to G-Code (linear and circular path) we put a text and the app makes it into G-Code. We can adjust the width and the height of the letters. If we choose to set only the width or the height, the program will automatically complete the other one to make the standard height/width letter ratio. In addition, in circular path we will need to fill in the Start angle and the End angle depending on the angle we want.

Linear path

Text : CNC-APPS

Font name: Arial

Width : 100

Height : 20

Circular path

Text: Hello world

Font name: Arial

Start angle: 60

End angle: 120

Radius: 100

Merge G-Code is an app that merges two or more files. As we can see in the examples below, we take two shapes with the same size and the program puts them together. In the case that the one files is smaller than the other the program will center the shape in the bottom left corner.

First file:

G21

G90

G00 X132.4399 Y123.1882

G02 X17.5333 Y26.77008 I74.98664 J74.97913

G02 X132.4399 Y123.1882 I74.98664 J74.97913

G00 X0 Y0

Second file:

G21

G90

G00 X150 Y150

G01 X150 Y0

G01 X0 Y0

G01 X0 Y150

G01 X150 Y150

G00 X0 Y0

Merge result:

G21

G90

G00 X132.4532 Y123.2091

G02 X17.5466 Y26.79094 I74.99994 J74.99999

G02 X132.4532 Y123.2091 I74.99994 J74.99999

G00 X150.0133 Y150.0209

G01 X150.0133 Y0.02086

G01 X0.0133 Y0.02086

G01 X0.0133 Y150.0209

G01 X150.0133 Y150.0209

G00 X0 Y0

Nesting Dxf app takes all the shapes and puts them in order. It places them by shape and size, after we have given the information of the height and width of the sheet. In addition we have to put the quantity of the sheet, the quantity of the default parts, the scale of the file and the minimum spacing between the parts. We can also choose the direction which the program is going to nest them (vertical or horizontal). The quantity of each part should be written as a number (DXF text) inside the part.

DXF File:

Basic input data:

Sheet width = 1000

Sheet height = 1000

Sheet quantity = 1

Default part quantity = 1

Minimum part spacing = 0

Scale = 1

Nesting angle step = 15

Part in part = Yes

Direction = Vertical

Result 1:

Direction = Horizontal

Result 2:

The Repeat app takes the shape we have provided and multiplies it as many times as we want it, either in a straight manner (example 1) or stagger them together (example 2).

G-code file:

G21

G90

G00 X132.4399 Y123.1882

G02 X17.5333 Y26.77008 I74.98664 J74.97913

G02 X132.4399 Y123.1882 I74.98664 J74.97913

G00 X0 Y0

Example 1:

Data:

Pattern type: Straight

X nest = 0

Y nest = 0

X offset = 0

Y offset = 0

Scrap clearance = 10

Pattern rows = 3

Pattern columns = 2

Result:

G21

G90

G00 X132.4532 Y123.2091

G02 X17.5466 Y26.79099 I74.99994 J75.00004

G02 X132.4532 Y123.2091 I74.99994 J75.00004

G00 X292.4531 Y123.2091

G02 X177.5465 Y26.79099 I234.9999 J75.00004

G02 X292.4531 Y123.2091 I234.9999 J75.00004

G00 X132.4532 Y283.209

G02 X17.5466 Y186.7909 I74.99994 J235

G02 X132.4532 Y283.209 I74.99994 J235

G00 X292.4531 Y283.209

G02 X177.5465 Y186.7909 I234.9999 J235

G02 X292.4531 Y283.209 I234.9999 J235

G00 X132.4532 Y443.2089

G02 X17.5466 Y346.7908 I74.99994 J394.9999

G02 X132.4532 Y443.2089 I74.99994 J394.9999

G00 X292.4531 Y443.2089

G02 X177.5465 Y346.7908 I234.9999 J394.9999

G02 X292.4531 Y443.2089 I234.9999 J394.9999

G00 X0 Y0

Example 2:

Data:

Pattern type: Stagger

X nest = 0

Y nest = 0

X offset = 0

Y offset = 0

Scrap clearance = 10

Pattern rows = 3

Pattern columns = 3

Result:

G21

G90

G00 X132.4532 Y123.2091

G02 X17.54662 Y26.79094 I74.99996 J74.99999

G02 X132.4532 Y123.2091 I74.99996 J74.99999

G00 X292.4532 Y123.2091

G02 X177.5466 Y26.79094 I234.9999 J74.99999

G02 X292.4532 Y123.2091 I234.9999 J74.99999

G00 X452.4532 Y123.2091

G02 X337.5466 Y26.79094 I394.9999 J74.99999

G02 X452.4532 Y123.2091 I394.9999 J74.99999

G00 X212.4532 Y283.209

G02 X97.54662 Y186.791 I154.9999 J235

G02 X212.4532 Y283.209 I154.9999 J235

G00 X372.4532 Y283.209

G02 X257.5466 Y186.791 I314.9999 J235

G02 X372.4532 Y283.209 I314.9999 J235

G00 X532.4532 Y283.209

G02 X417.5466 Y186.791 I474.9999 J235

G02 X532.4532 Y283.209 I474.9999 J235

G00 X132.4532 Y443.209

G02 X17.54662 Y346.791 I74.99996 J394.9999

G02 X132.4532 Y443.209 I74.99996 J394.9999

G00 X292.4532 Y443.209

G02 X177.5466 Y346.791 I234.9999 J394.9999

G02 X292.4532 Y443.209 I234.9999 J394.9999

G00 X452.4532 Y443.209

G02 X337.5466 Y346.791 I394.9999 J394.9999

G02 X452.4532 Y443.209 I394.9999 J394.9999

G00 X0 Y0

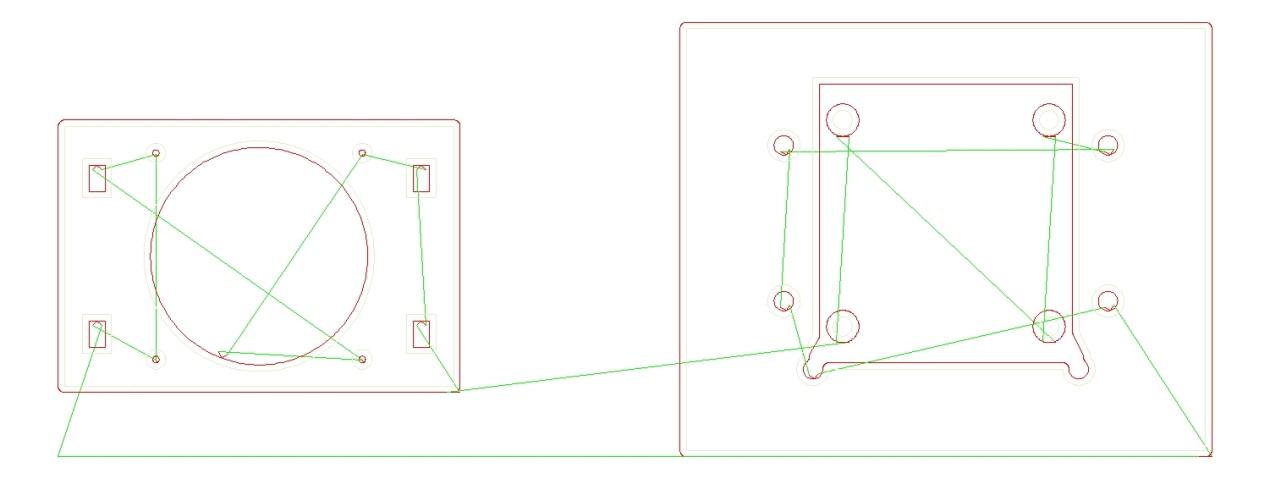

In the Compare images app the program takes the two shapes and tries to find what differences they have.

Image 1:

Image 2:

Result image:

The differences are in white color.

The Compare texts app takes the two texts, finds the differences they have, and marks them with red.

First text:

This is 1st text

A new line

A same line

Second text:

This is 2nd text

Test

A same line

Result:

In the Edit G-Code app we give the proper commands and the program gives us a visual representation of what the shape will be like, in order to help us see and correct any possible mistakes.

G-Code:

G00 X10 Y10

G01 X10 Y0

G01 X0 Y0

G01 X0 Y10

G01 X10 Y10

G00 X0 Y0

Result:

The Mirror app help us mirror the shape base on the X or the Y axis, as we see in the examples below.

Original G-Code

Mirror axis = X Axis

Result:

Mirror axis = Y Axis

Result:

In the Move G-Code app we put the X and Y coordinates depending on how far we want to move the shape.

Example:

X distance = 100

Y distance = 100

The Replace app help us replace one or more commands with another command or with nothing. For example, as we can see below, we replace the commands M1002 with M500 and the command M08 with nothing.

Source G-Code file:

G21

G90

G00 X150 Y150

M1002

G01 X150 Y0

G01 X0 Y0

G01 X0 Y150

G01 X150 Y150

M08

G00 X0 Y0

M02

Replacement commands:

M1002=M500

M08=

Result G-Code file:

G21

G90

G00 X150 Y150

M500

G01 X150 Y0

G01 X0 Y0

G01 X0 Y150

G01 X150 Y150

G00 X0 Y0

M02

In the Rotate app we give the angle of which the shape is going to rotate.

Example:

Angle = 90

In the Scale app we transform the shape in the height (X axis) and width (Y axis).

Example:

Scale X = 0.5

Scale Y = 1

Result:

The Flatten 3D app takes the 3D shape and males it 2D.

3D file:

Result:

The Raster to vector app takes digital picture and makes into a shape

Example:

Outline = No

Smooth = Yes

Smooth factor = 0

Connect = Yes

Connect factor = 0

Clean = Yes

Clean factor = 0

Result:

Sheet width |

71.152 |

Sheet height |

69.028 |

Sheet area |

4911.48 |

Path length |

508.7883 |

Parts area |

3205.43 |

Scrap area |

1706.05 |

In the Collision detection app the program tries to find possible collisions that are happening between the lines.

Original file:

Result:

There is a problem inside the small red circle.

In the Fix DXF file app the program takes all the little spots and shapes from the general shape and removes them.

Original file:

Result:

In the Optimize app the program correct the path which the machine takes to reach from one point to another, by not taking random routes but by using the traveler algorithm.

Original file:

Result:

In the Image engraving app we take a grayscale image and the program ‘’prints’’ it by carving the surface of the material. Depending on how dark or light the grey is, is going to determine how deep the tool is going to carve.

Original picture:

Data:

X step: 0.2

Y step: 0.2

Material width: (0=image width) 200

Material height: (0=image height) 150

Material thickness: 30

Min F: 5

Max F: 20

Outline on: no

Negative: no

Result 1:

Data:

Outline on: no

Negative: yes

Result 2:

The same with lower quality.

Data:

X step: 0.5

Y step: 0.5

Result 3:

In the STL to G-CODE (mill) app the program takes the STL file and puts the 3D shape into a poll (X axis) and the tool in the Z axis. Afterwards, the tool continuously carves the 3D shape as the poll keeps rotating.

Original file:

Slices distance = 4

Tool diameter = 20

Axis diameter = 30

Rotation angle = 0

Tool length = 250

Secure position = 300

Result:

In the Table mill to G-Code app we give the information’s of the Tool Diameter, the Table length/width, the Depth and lastly the movement we want, which can be along the X axis or the Y axis.

Tool Diameter = 1

Table length = 100

Table width = 50

Depth = 10

Movement = Along X axis

Movement = Along Y axis

The DXF to G-Code (Knife) app finds all the corners and parts of your shape, by taking a small line and moving it across.

DXF file:

Code header = T1

Code for UP = G0 Z10

Code for DOWN = G0 Z0

Code footer = G0 A0

Result G-CODE:

G90

T1

G0 Z10

G0 A0

G0 X9.558 Y16.637

G0 Z0

G0 Z10

G0 A90.000

G0 Z0

G1 X9.558 Y52.037

G0 Z0

G0 Z10

G0 A0.000

G0 Z0

G1 X30.974 Y52.037

G0 Z0

G0 Z10

G0 A270.000

G0 Z0

G1 X30.974 Y33.452

G0 Z0

G0 Z10

G0 A0.000

G0 Z0

G1 X52.391 Y33.452

G0 Z0

G0 Z10

G0 A90.000

G0 Z0

G1 X52.391 Y69.028

G0 Z0

G0 Z10

G0 A0.000

G0 Z0

G1 X71.152 Y69.028

G0 Z0

G0 Z10

G0 A270.000

G0 Z0

G1 X71.152 Y0.000

G0 Z0

G0 Z10

G0 A180.000

G0 Z0

G1 X0.000 Y0.000

G0 Z0

G0 Z10

G0 A60.124

G0 Z0

G1 X9.558 Y16.637

G0 Z0

G0 Z10

G0 A0

G0 X0.000 Y0.000

G0 Z0

G0 A0